Robotic Software / Teaching Robots

On this project my role was PM, Lead ID, and researcher: I went onsite, conducted the FEA, gathered all the research and photos, developed the design document/content, and handed off storyboarding ID work to two IDs working the content as I trained them on technical content development.

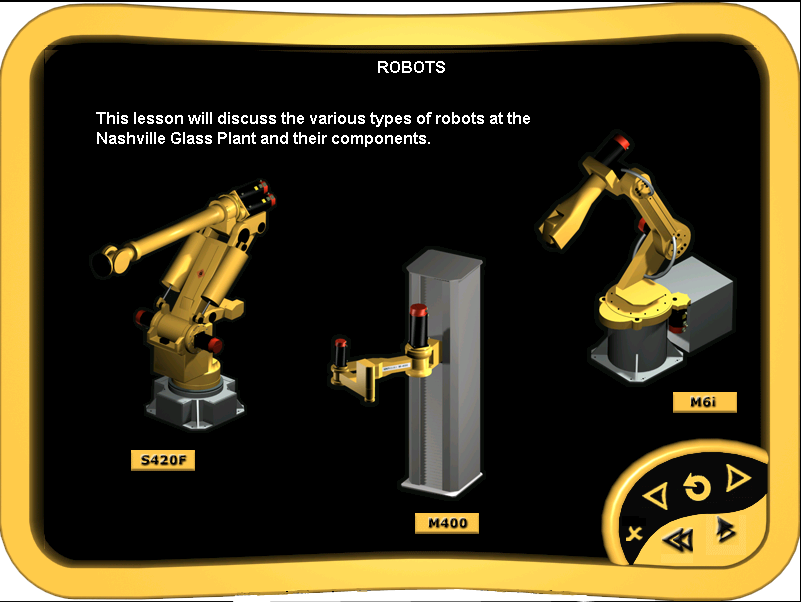

This program - Robotic Software and Teaching Robots for operators and skilled trades - was complex technical CBT and EPSS covering fundamental robotic principals, robot types and components, maintenance, operation, and troubleshooting. The primary focus was on robot system software, which required “teaching” robots how to move within an existing software program to do the tasks required of each robot. For example, one robot picked up windshields from a queue and placed them on one of two adjacent Lehr furnaces for annealing.

Content was specific to each of six user groups to include operators, maintenance, and skilled trades. The system included a programming/operation hand-held pendent that came with robots, computer software that the pendent and robot interacted with, and the positions and axes of the robot itself and the zone within which the robot would operate.

The GUI for this is unusual. At the time we were experimenting with various designs. Boards were created in Word and handed off to a developer who built the program in Authorware. The program ran locally on the plant floor via computer or kiosk.