Major Projects

Boeing 787 Training Program

2006-2008: My first project with Boeing was to develop training for various manufacturing and safety processes for the 787 that would come online in a few years. At the time they were just building the first two planes, and we worked alongside leads and engineers while specifics were determined.

Explosive Detection Dog Program

2003-4: This program leveraged a world-class bomb dog training program and created a pilot program for the US Army. The trainers and dogs from this program were ultimately deployed to Afghanistan and Iraq. Easily one of the best projects I’ve had the opportunity to work on and make a positive and lasting contribution.

Web-Based Training for CBRNE Program

2003-4: I was PM and Lead ID on this $1.2M project, which was the conversion of select portions of a 750 hour accredited training program that focused on the knowledge and skills required to work in fixed and mobile chemical, biological, radiological, and nuclear (CBRN) labs. The task was to migrate basic information to online learning and minimize the time required on site for in-person classes, labs, and field exercises, in addition to other tasks.

WMD First Responder Terrorism Response Training Program

2002-03: Worked as an ID on this accredited training program that focused on the knowledge and skills required to work in fixed and mobile chemical, biological, radiological, and nuclear (CBRN) labs. The program is a multi-week, four-level (Intermediate through Advanced) training program for first responders, spanning CBRN terrorist threats.

Computer Hardware Demanufacturing and Recycling Equipment Training

2002: Training program for a computer hardware demanufacturing/recycling facility that took computer hardware apart, separated the materials, and recycled those materials into pellets and other forms that could then be resold as raw materials.

Automated Information Systems (AIS) Security for Managers

2002: The AIS Security for Managers course was a CBT I designed for the US State Department. The course prepared managers for their assigned responsibilities in protecting the State Department’s automated information systems in a post-9/11 environment.

TTC T-BERD 310 Training

Worked as an ID developing classroom training and hands-on labs for the TTC T-Berd 310, and portable transmission line testing device used in telecommunications.

WBT for USMC MOLLE Pack

Technical program for Marines on new type of backpack, vest, and body armor with over 50 individual pieces. Program includes simulated planning of loads per 7 deployment scenarios.

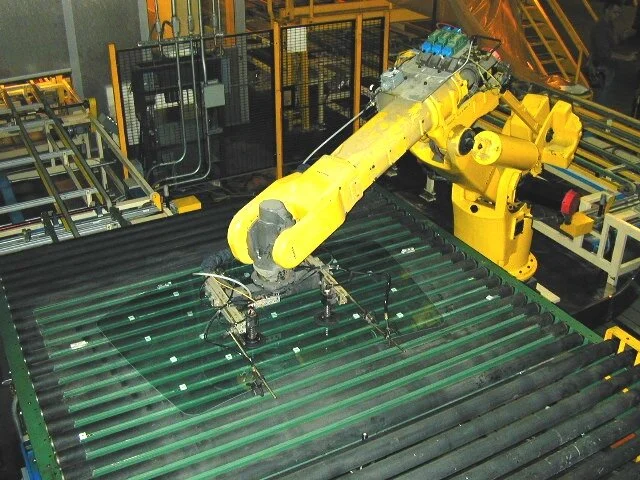

Robotic Software / Teaching Robots

2001: Complex technical CBT and EPSS for operators and skilled trades, covering fundamental robotic principals, robot types and components, maintenance, operation, and troubleshooting.

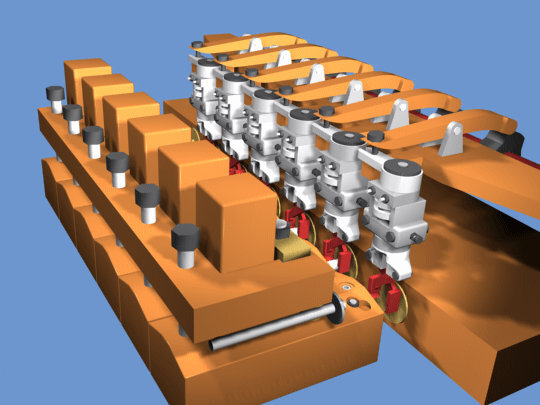

Glasstech Lehr Pressform Furnaces

2001: CBT/EPSS for Lehr furnace operators making windshields. The program covered furnace (and related equipment) components, flows, safety, quality, maintenance, troubleshooting, and repair.

Heat Treat Department/Holcroft Carburizing Furnaces

2001: PM and Lead ID on CBT/EPSS for operators and skilled trades to cover an entire Heat Treat department, three gas generators, five batch furnaces, and seven pusher-type carburizing furnaces.

Medium and Large Injection Molding Press Department

2001: CBT/EPSS for machine operators of 55 different injection molding machines. Operators were responsible for all aspects of machine production including operation, changeover, maintenance, troubleshooting, quality control, and repairs.

Die Cast Hydraulics for Machine Repair Personnel

2000: CBT/EPSS covering hydraulic aspects of hot metal die cast part forming machines, trim presses, and extractor arms. CBT dealt with basic concepts like hydraulic components, valve operation, flows, and how to troubleshoot using blue prints.

National Cold Headers (Cold Parts Formers) for Operators

2000: CBT/EPSS program for 7 different metal parts forming machines covering machine components, process flow, safety, operating procedures, changeover, maintenance, and troubleshooting for each different machine.

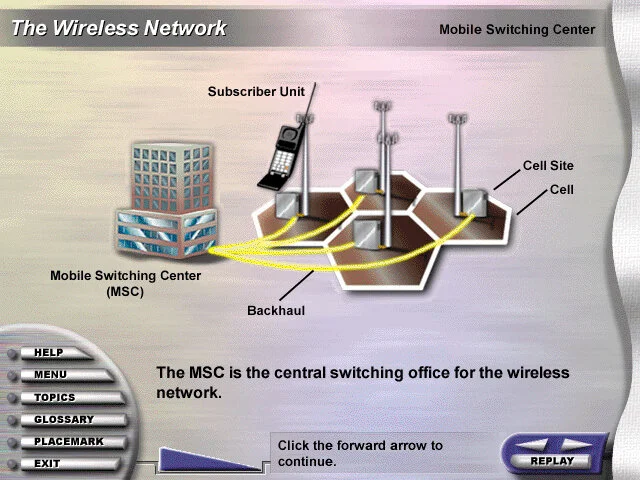

Telecommunication Field Technician WBT

1999: As an ID on this project I developed lessons for field technicians on transmission lines, base stations, and antennas covering functionality, components, optimization, and troubleshooting.

Bethlehem Steel Hot Strip Mill Reversing Rougher and Coil Box CBT/EPSS

1998: CBT/EPSS programs that covered hot steel flow through an entire hot strip mill line. Covered table control up to Reversing Rougher and Coil Box, including components, flows, computer controls, operating procedures, maintenance, and troubleshooting.

Ocean Spray Juice Blending Operations CBT/EPSS

1998: CBT/EPSS training program covering juice blending operations, designed for new operators. Covers tank names, layout, flows, components, flow valves, safety, computer systems, operations, juice batch operations which includes making, monitoring, transferring batches. EPSS for Juice Blend Operations detailed tank layout and flows, mixing procedures, batch testing and juice specifications, batch dumping, preparation of batches, monitoring, safety, and internal customer needs.

Case Packer EPSS for Vista Bakery

1997: Instructional design role to build an EPSS for case packer operations, troubleshooting, and maintenance.

CBT Projects for Weyerhaeuser

1996: As an ID I researched and developed CBT modules for machines and processes in the brownstock department in a fine paper mill. Lessons covered components, system flows, valve numbers and locations, operations, maintenance, and troubleshooting.

Paper-based ILT for Georgia-Pacific Mills

1993-95: Paper-based/audio lessons to assist standup classes taught by operators/SME’s. Covered 40 types of machines, processes, and systems in fine paper, tissue, and paperboard mills, including most machinery components, flows, and operating procedures. PM on board mill and fine paper mill project budgets/timelines.